TWINSTOP®

Our patented fall arrester:

The central element of our fall protection program

Fall protection systems are subject to approval according to EN 353-1. After accidents, some of them fatal, occurred with conventional, simple systems in the past, this standard was improved in 2015. Based on the findings about the weaknesses of previous systems, the Twinstop® concept was developed long before the legal adaptation of the testing requirements.

The simple mode of operation of our Twinstop® fall arrester guarantees safe and error-free handling.

SPECIAL FEATURE

The fall arrester locks both vector-based and speed-dependent. It is based on a simple and robust mechanism. This guarantees reliable operation, less downtime due to maintenance and, as a result, cost benefits.

Approval

The fall arrester is approved according to EN 353-1:2014+A1:2017 for the rails of MKL-Technik GmbH, as well as several competitor rails – such as the guide rails or ladders of Safety Climbing Systems GmbH. This means that it can also be installed in existing rails with little effort.

Areas of application

The system can be installed above and below ground and can also be used in locations with public traffic thanks to various safety mechanisms and access barriers. In terms of height and substrate, there are no limits to our system.

Functionality

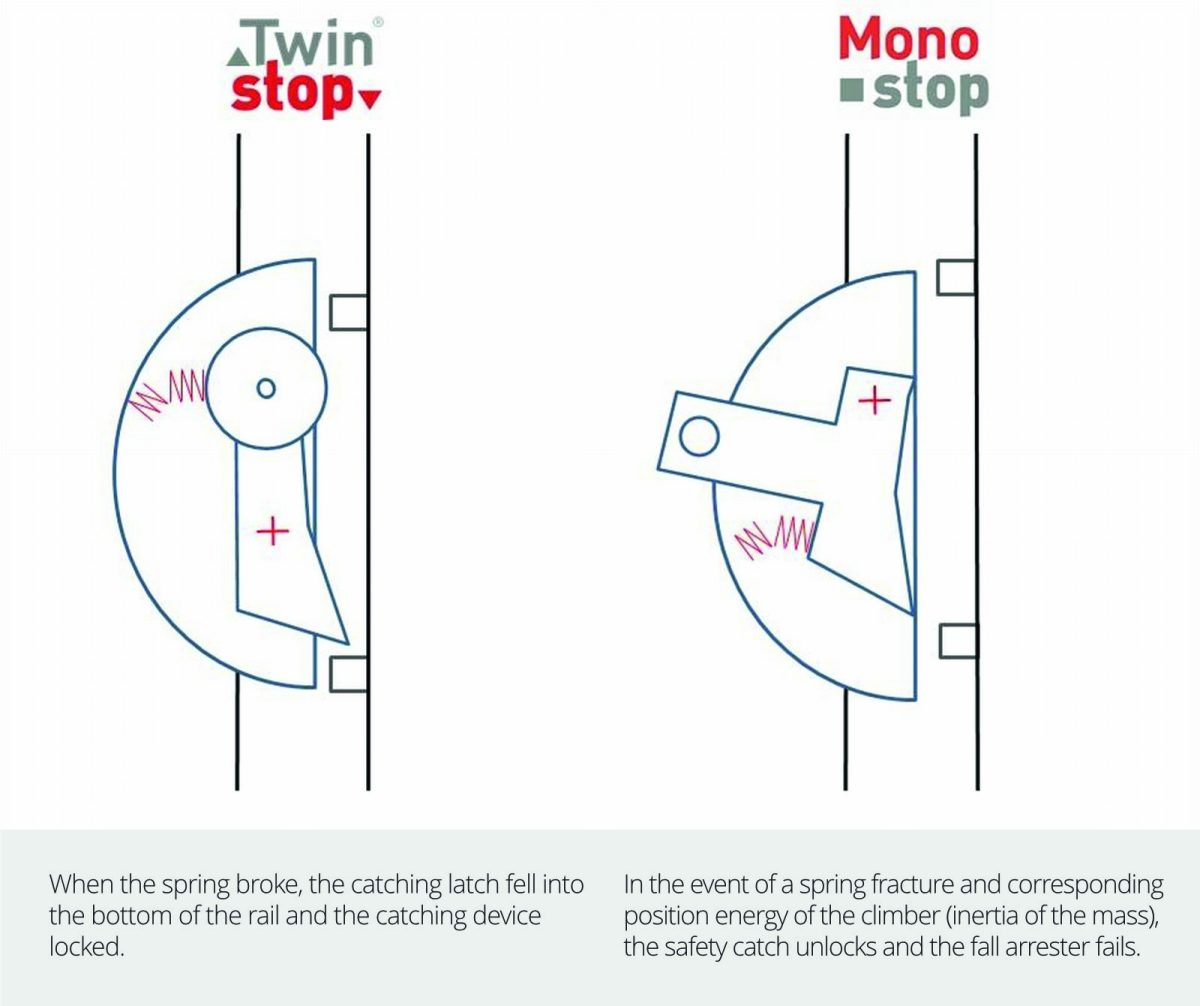

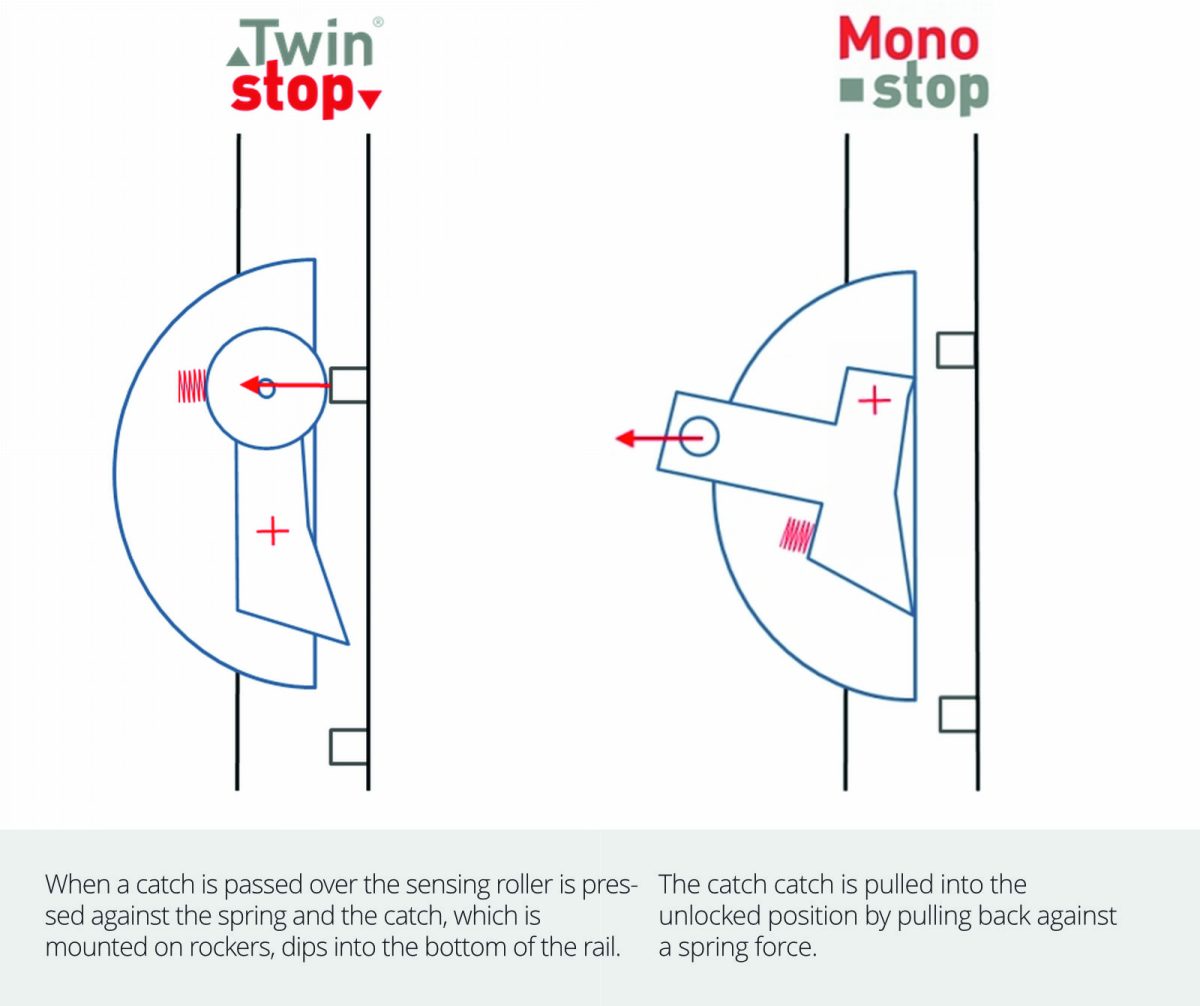

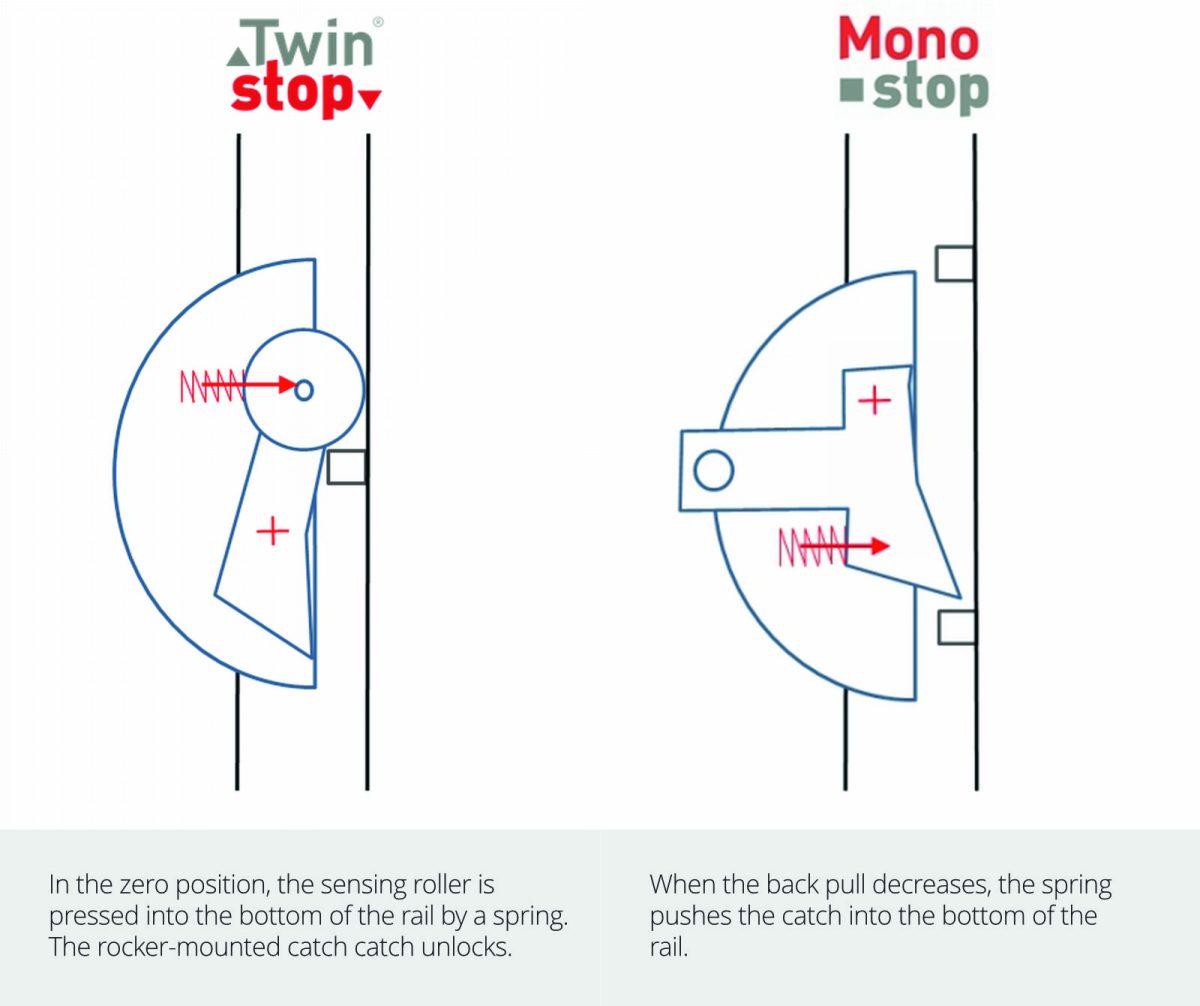

With these graphics we explain the exact function of our revolutionary collection system

Step 1

The sensing roller runs in the bottom of the rail. The pawl connected to the roller rests in the housing.

Step 2

The sensing roller passes over a catch notch. The pawl dips into the rail and is reset by means of a spring after passing over it.

Step 3

If the speed becomes too high, the pawl has no time to spring back. The pawl moves against the catch notch and locks. The pawl is additionally pressed into the rail by the anchor point, which is mounted according to the back-pull principle. The anchor point is not directly connected to the pawl. This means that the pawl cannot be released again by careless movements of the climber. The positive guidance of the pawl ensures that the locking process is not affected by spring breakage or contamination.

Our advantages

Why a new system?

According to the EN 353-1 guideline, the following accidents can happen with classic climbing systems – and this is where our innovative system scores over its predecessors!

The climber squats during the climb, e.g. to grab something, due to cardiovascular problems, nausea, etc. The rigid connection with the fall arrester shifts the climber’s center of gravity. In this position, it is increasingly difficult to get back to the top under your own steam. In extreme cases, the person falls into a “head-over-heels” position, the fall arrester unlocks, and the person falls.

In the situation of low friction between the fall arrester and the guide rail, the climber and the fall arrester accelerate at the same rate in the event of a fall.

This means that locking is no longer possible purely via the geometry of the fall arrester. The relatively weak spring of the safety catch must be

Pull the mass of the climber towards the guide rail until the fall arrester locks in the catch notch.

Tests by the British HSE show that the distance required for this can be large, that the impact force is far above the permitted 6 kN.

The operating principle of the MKL-Technik GmbH Twinstop® fall arrester is designed to be redundant and thus fail-safe, which we achieve by means of a mechanism positively guided in the C-profile of the guide rail. Compared to systems that operate exclusively on back pull or offer only simple functional safety, this type of speed-dependent release has several advantages, as shown here in comparison to our old monostop.

Larger drop distances can occur if the guide rail is mounted overhanging.

Depending on the rail angle and design, the fall arrester’s blocking function can be completely disabled.

Since the blocking function of the Twinstop® fall arrester is speed-dependent – without the influence of external forces – the fall arrester function is also guaranteed in overhanging guide rails.

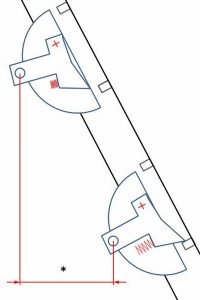

Tested to max. 25°deviation from the perpendicular.

* Required dimensional deviation to trigger catching process, in relation to the perpendicular.

There are various factors that influence the intact function of a rotor of conventional design:

- Position of the anchor point

- Webbing material

- Lanyards

In the case of fall arrest systems whose function is based on a change in the application of force at the anchor point, the direction of force can be influenced or interrupted by incorrect behavior on the part of the climber in such a way that the fall arrest function fails. Such influences are:

- Working on the ladder without additional safety

- Attachment to the abdominal eyelet of the harness

- Do not follow the 3-point method (at least two hands one leg or two legs and one hand on the ladder).

- Use longer fasteners

- Reaching into the anchor point to manually unlock the fall arrester when driving through a manhole

In daily routine, such errors can easily happen, so it is important that a system is designed to function safely even in such situations, protecting the user from a crash.

The Twinstop® fall arrester functions even under the above-mentioned circumstances and offers both max. physical safety for the user, as well as max. legal security for its client.